Your Cart is Empty

START 2026 OFF RIGHT - JOIN THE FREE-MOTION MASTERY FATHER'S DAY QUILT-ALONG! CLICK HERE

In one of my classes in Fredericksburg, a student told me about a problem she was having with her thread breaking while doing free-motion quilting. We discussed various possibilities that might be causing it and the came around to the question of needles. The topic came up again in last night's FMM30 Club class so I thought I'd share some of the same information with you all.

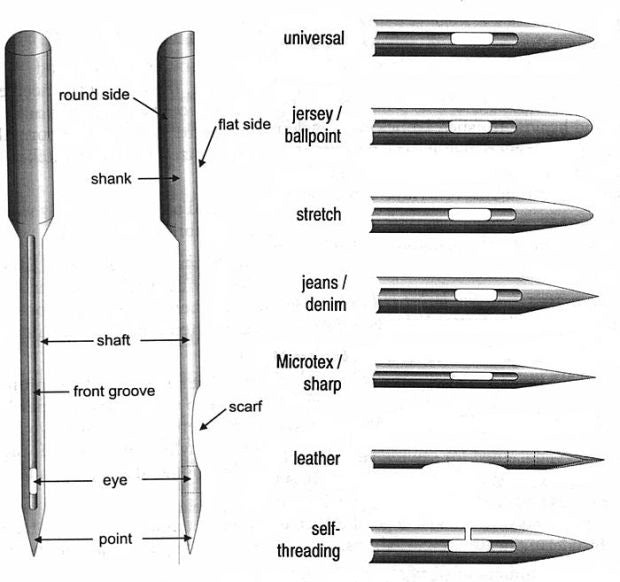

If you search Google for images of needles you'll find this diagram in various places. It's really useful because it shows you the structure of a sewing machine needle and also compares the shapes of the points. You can see right off that some are sharper than others. Just going by this, you can tell that a Universal or Microtex needle would be the best choice for quilting because of the sharp point. Quilting needles are sharp like MIcrotex but have a stronger shaft. In my free-motion quilting classes I have students use the type of needle that they normally sew with, because they know their machines will "like" it. Later, when they are more confident with their FMQ skills, they can test other needle types.

The diagram of the front of the needle shows a groove down the center. Keep in mind that as the thread goes through a sewing machine, it passes through the bobbin race about 35-40 times before it becomes part of an actual stitch. Each time, it loops around the bobbin race and then is tightened into a stitch by the hook, that part in the slot above the needle that goes up and down.

The groove down the front of the needle is like a long skinny cave that lets the thread hide in it to avoid being rubbed and frayed as it goes through the bobbin race. If the needle is too small for the thread, the thread bulges out, rubs against the bobbin parts and frays until it breaks.

Another one of my students last week told me she was having thread breakage problems while she was sewing a sheer lightweight fabric. She had chosen a smaller needle -- 75/11 -- because of the weight of the fabric. But she was still using a regular sewing weight thread (50 weight). I explained to her that the weight of the thread determines the size of the needle, and that her needle was too small for the thread. The thread was breaking because it was bulging out of the groove on the needle. The solution was to either use a larger needle or a finer thread -- 75/11 needle with a 60 or 70 weight thread, or 80/12 needle with a 50 weight thread. Either way, the thread will sit down into the groove and the breakage problem will be solved. (An additional solution might be to use a topstitching needle with a bigger eye which will also reduce friction on the thread.)

Comments will be approved before showing up.